Precision in Every Part, Crafted for Excellence

Pioneers in Bicycle and Automobile Part Manufacturing in Malaysia and Beyond.

50 Years of Expertise, Trusted Worldwide

From our roots in Japan to 15 years of excellence in Malaysia, Showa Metal Industries has redefined precision manufacturing. With monthly production capability over 50 million parts produced and exported to 7 countries, we’re committed to delivering high-quality bicycle and automobile sub-components.

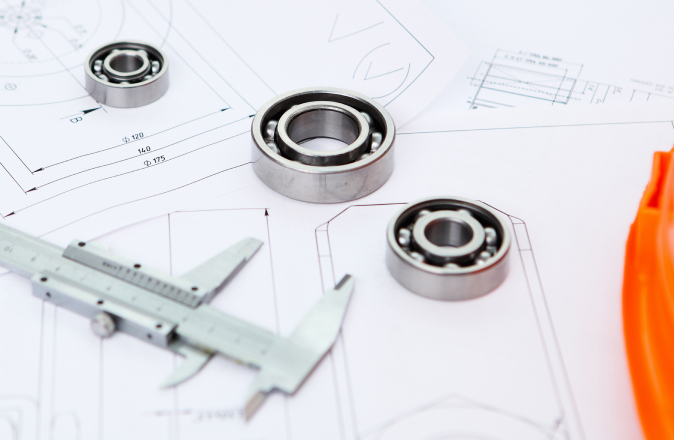

Precision Forging

The Core of Showa Metal Advance’s Manufacturing Excellence

At Showa Metal Advance, our manufacturing foundation is built upon advanced cold forging technology, allowing us to mass-produce high-precision metal components with superior efficiency and cost-effectiveness. By integrating cold forging with machining processes, we achieve enhanced durability, reduced material waste, and complex part geometries that exceed industry standards.

High-Precision Production

Ensures tight tolerances and superior quality for complex components.

Cost-Effective & Sustainable

Reduces material waste while optimizing efficiency and production costs.

Scalability & Customization

Adapts to varying production volumes and specific design requirements.

Our Expertise, Your Advantage

Comprehensive Solutions for Bicycle and Automobile Part Manufacturing

Manufacturing & Development

Precision-crafted parts tailored to meet industry demands.

Design Services

Innovative designs to enhance performance and reliability.

Customized Solutions

Tailored components to meet complex specifications.

What Sets Us Apart

Advanced Forging Machines

Advanced forging machines with multi-station capabilities for superior complexity.

Premium Japanese Raw Materials

90% high-grade raw materials imported from Japan, ensuring unmatched quality.

ISO-Certified Processes

ISO-certified processes for guaranteed precision and reliability.

Global R&D Collaboration

Seamless R&D collaboration between Japan and Malaysia.

Our Machines & Technology

Cutting-Edge Technology for Precision Manufacturing

Up to 21 forging machines and 30 CNC machines, we’ve grown to meet the highest standards.

Our forging machines handle higher complexity parts, offering exceptional productivity and minimal material waste.

Industries We Serve

Favoured by Top Manufacturers

Favoured by top manufacturers in the cycling and automotive industries.

Exporting Excellence Across Asia

Exporting high-quality components to Malaysia, Japan, China, Thailand, Vietnam, and beyond.

Malaysia

Japan

China

Thailand

Vietnam